In the world of precision engineering and metal fabrication, surface grinding machines play an essential role. These machines are designed to produce smooth, flat surfaces with incredible accuracy, ensuring that parts meet exact dimensional tolerances and achieve the desired finish.

Whether used in automotive, aerospace, or toolmaking industries, surface grinders form the backbone of many high-precision manufacturing processes.

What Is a Surface Grinding Machine?

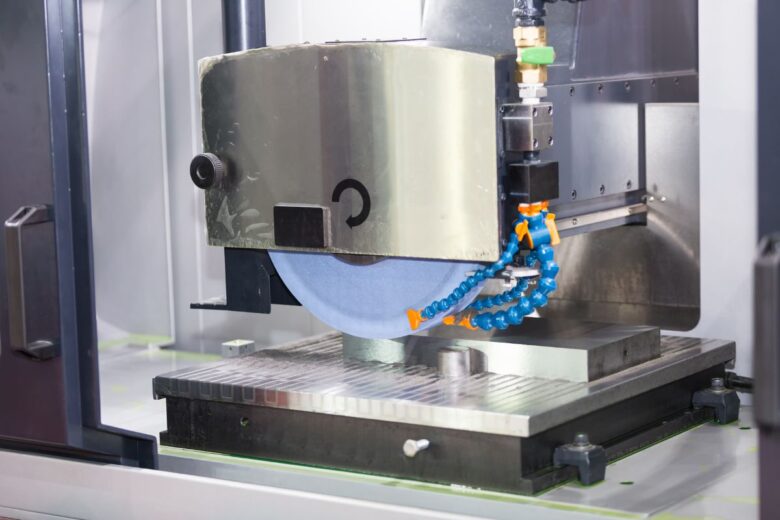

A surface grinding machine is a type of grinding equipment used to smooth the surface of metallic or non-metallic materials. It employs a rotating abrasive wheel to remove material from a workpiece, gradually refining it to achieve a flat and uniform finish. This process not only improves the aesthetic appearance of components but also enhances their performance by ensuring proper fitment and reduced friction.

The grinding wheel, usually made from abrasive materials like aluminium oxide or silicon carbide, is mounted on a spindle and rotates at high speed. The workpiece is held securely on a magnetic chuck or table, allowing the machine to make precise passes until the required level of smoothness is reached.

For a deeper overview of how these machines operate and the different models available, you can explore this Grinding Machine Surface guide.

Types of Surface Grinding Machines

There are several variations of surface grinders, each designed to serve specific industrial purposes:

- Horizontal spindle surface grinders – The most common type, these machines use a horizontally mounted grinding wheel that moves across the surface of the workpiece. They are ideal for achieving a fine, flat finish on large components.

- Vertical spindle surface grinders – In this design, the grinding wheel is positioned vertically, allowing for rapid material removal and an efficient grinding process.

- Single disc and double disc grinders – These are specialised machines capable of grinding two surfaces simultaneously, making them suitable for high-volume production environments.

- CNC surface grinders – Equipped with computer numerical control, these advanced machines allow for automated precision grinding. CNC technology reduces human error and enhances repeatability across multiple workpieces.

Key Components and How They Work Together

Surface grinding machines are built around several crucial components that work in harmony:

- Base and column: These provide the structural integrity and rigidity necessary for precision work.

- Work table: The platform that holds the workpiece, typically equipped with magnetic clamping systems for ferrous materials.

- Grinding wheel and spindle: The core of the operation, responsible for the actual material removal.

- Coolant system: Helps dissipate heat and prevent warping or burning of the workpiece.

- Control system: In CNC models, this is the digital brain that dictates movement and pressure.

Each component must be meticulously maintained to ensure consistent, high-quality output.

Applications of Surface Grinding Machines

Surface grinding is used across a wide range of industries. In automotive manufacturing, it is used to prepare engine blocks and gear components. The aerospace industry relies on it for parts requiring extreme precision, such as turbine blades and landing gear components. In toolmaking, surface grinding ensures that dies and moulds achieve perfectly flat surfaces essential for forming materials accurately.

Beyond these sectors, surface grinding machines are also used in research laboratories and maintenance workshops for refurbishing worn parts and preparing testing surfaces.

Benefits of Using Surface Grinders

The advantages of surface grinding machines are significant. They include:

- Exceptional accuracy: Capable of achieving tolerances as fine as 0.002 mm.

- Improved surface finish: Produces mirror-like surfaces ideal for critical components.

- Versatility: Suitable for metals, ceramics, and even composites.

- Extended component Life: Reduces wear and tear by ensuring perfectly matched surfaces.

- Automation potential: CNC systems allow for high-speed, repeatable production.

Final Thoughts

Surface grinding machines remain an indispensable part of modern engineering and manufacturing. Their ability to deliver precision, consistency, and quality makes them vital for industries that rely on flawless surfaces and tight tolerances.

Whether used for finishing small components or large industrial parts, these machines continue to push the boundaries of what’s possible in metalworking.