Surface finishing is essential across many industries, from automotive restoration to aerospace component preparation.

Among the various techniques available, wet blasting has become increasingly recognised for the level of control and consistency it offers.

At the centre of this method is the vapor blasting machine, a system designed to combine water and abrasive media to produce smooth, refined surfaces suitable for further processing or use.

What Is Wet Blasting?

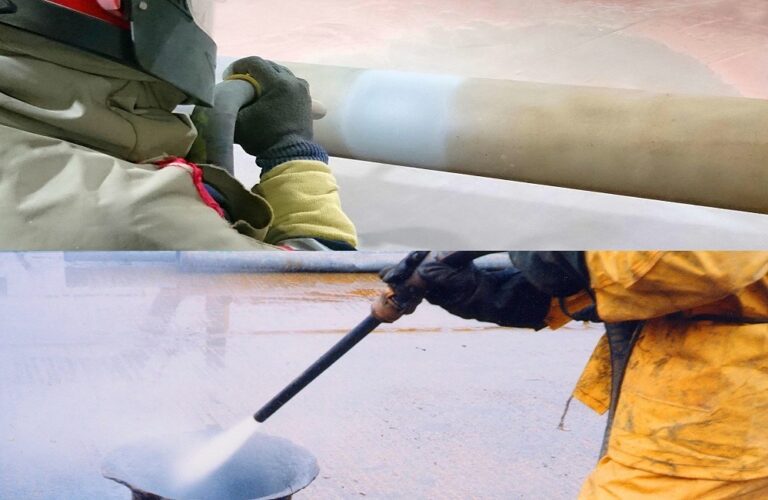

Wet blasting, sometimes referred to as liquid honing or vapour honing, is a process in which water acts as a cushioning and lubricating agent for abrasive particles.

Unlike dry blasting, which propels media with air alone, wet blasting suspends abrasive within water, creating a slurry.

This slurry is then directed at the target surface under pressure.

The result is a less aggressive yet highly effective method of cleaning, smoothing, or preparing surfaces.

Because water reduces friction, it creates a finer, more uniform finish than many dry methods, making it especially useful where precision matters.

Components of a Wet Blasting System

A typical system incorporates several key features designed to maintain consistent slurry flow and controlled pressure:

- Blast cabinet – Contains the environment in which blasting takes place, preventing media and water from escaping.

- Slurry pump – Keeps abrasive and water in constant circulation, ensuring even delivery to the blast nozzle.

- Nozzle system – Regulates the pressure and direction of the slurry stream.

- Filtration and settlement areas – Separate usable media from waste, allowing the system to maintain efficiency.

These components work together to produce a stable process that is repeatable and suitable for delicate or complex surfaces.

Applications Across Industries

Wet blasting is valued for its versatility. It can be applied to metals, plastics, ceramics, and even composite materials.

Some common uses include:

Automotive Restoration

Technicians use the process to remove oxidation, paint, carbon deposits, and grime from engine components without damaging the underlying metal.

It is often chosen for aluminium parts due to the refined satin finish it produces.

Aerospace Engineering

Precision is critical in this sector. Wet blasting allows for controlled surface preparation before coating, bonding, or inspection.

The method preserves component dimensions while improving adhesion for subsequent layers.

Manufacturing and Tooling

Cutting tools, moulds, and machined parts benefit from the reduced surface roughness created by wet blasting.

This can extend the life of components and improve performance, particularly where friction or wear is a concern.

Conservation and Restoration

Because it is gentle compared with more forceful blasting techniques, wet blasting can be used on delicate objects, helping remove corrosion or deposits while preserving detail.

Benefits of Wet Blasting

Several advantages contribute to the growing use of this method:

- Reduced dust – Water binds abrasive particles, limiting airborne contamination and improving working conditions.

- Consistent finish – The cushioning effect of water allows for even material removal.

- Lower risk of surface damage – Sensitive components are less likely to become pitted or warped.

- Improved cleanliness – The process simultaneously cleans and finishes, minimising the need for additional steps.

These characteristics make wet blasting a practical option when precision and surface integrity are priorities.

Process Control and Adjustability

Operators can fine-tune the blasting process by adjusting variables such as slurry concentration, pump speed, water pressure, and abrasive type.

This adjustability makes the technique suitable for both heavy cleaning tasks and light surface refinement.

Selecting the correct media is especially important. Glass bead, aluminium oxide, silicon carbide, and other abrasives can be used depending on the required finish.

Finer media combined with lower pressure produce smoother results, while coarser materials allow for more aggressive cleaning when necessary.

Maintenance and Care of Equipment

Regular maintenance ensures consistent performance. Key tasks often include:

- Monitoring slurry levels and consistency

- Cleaning nozzles and hoses to prevent clogging

- Replacing worn abrasive

- Checking seals and filters for wear

- Inspecting pumps to maintain steady flow

Proper upkeep prolongs the lifespan of the system and helps maintain reliable surface outcomes.

Safety Considerations

Although wet blasting reduces dust exposure, standard safety practices still apply.

Operators should use appropriate protective clothing, gloves, and eye protection. Ensuring adequate ventilation and following manufacturer guidelines further supports a safe working environment.

Conclusion

A vapor blasting machine offers a controlled, clean, and versatile method for surface preparation across numerous industries.

By combining water with abrasive media, it provides an effective approach to achieving refined, uniform finishes while preserving material integrity.

This balance of precision and gentleness makes wet blasting a suitable choice for both routine maintenance tasks and high-specification engineering work.